304L stainless steel is a low-carbon version of the widely used 304 stainless steel. It is an austenitic chromium-nickel alloy with excellent corrosion resistance, mechanical properties, and workability.

The key feature of 304L stainless steel is its low carbon content, which makes it less susceptible to carbide precipitation during welding. This property improves the weldability of the material, ensuring strong and reliable welds.

304L stainless steel, also known as ultra-low carbon stainless steel, is a kind of universal stainless steel material, widely used in the production of equipment and parts requiring good comprehensive properties (corrosion resistance and formability).

Equivalent Material

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 304L | 1.4307 | 00Cr19Ni10 | SUS304L | |

Standard Specification

| Thickness | 4mm-100mm | ||||||

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc | ||||||

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | ||||||

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc | ||||||

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) | ||||||

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

||||||

Composition Content

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 304L | Min. Max. |

≤0.03 | ≤2.0 | ≤1.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | / | 9.0~12.0 | / |

Yield strength (N/mm2) ≥205

Tensile strength ≥520

Elongation rate (%) ≥40

Hardness HB ≤187 HRB≤90 HV ≤200

The density of 7.93 g · cm – 3

Specific heat c (20 ℃) 0.502 j. (g · c) – 1

Thermal conductivity λ/W(m·℃)-1 (at the following temperatures /℃)

20 100 500

12.1 16.3 21.4

Linear expansion coefficient α/(10-6/ ° C) (at / ° C between the following temperatures)

20 ~ 200 20 ~ 300 20 ~ 400

16.0 16.8 17.5 18.1

Resistivity 0.73 Ω·mm2·m-1

Melting point 1398 ~ 1420℃

Characteristic machining technology

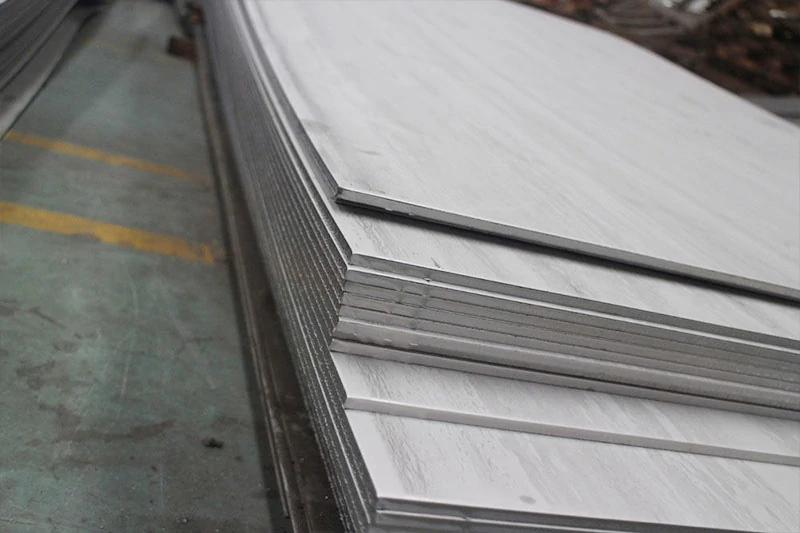

1D — The surface has discontinuous granular shape, also known as fog surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

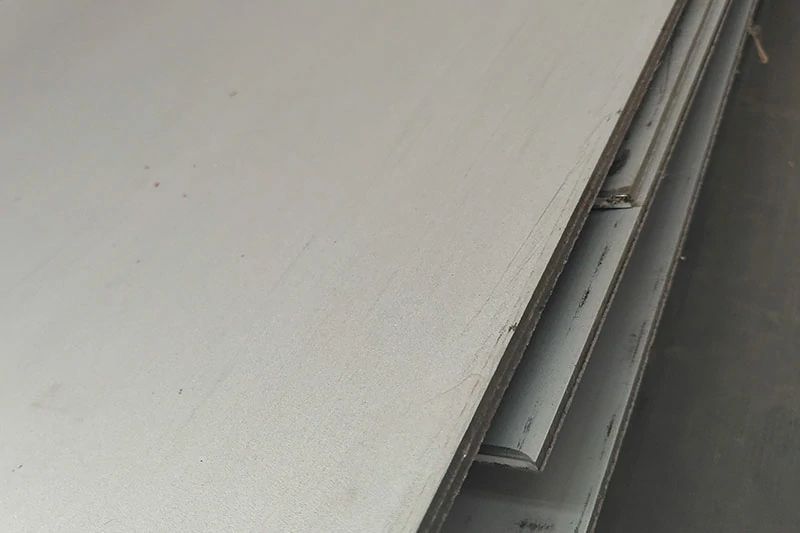

2D – A slightly silvery white colour.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2B — Silver white with better gloss and flatness than a 2D surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + quenching and tempering rolling.

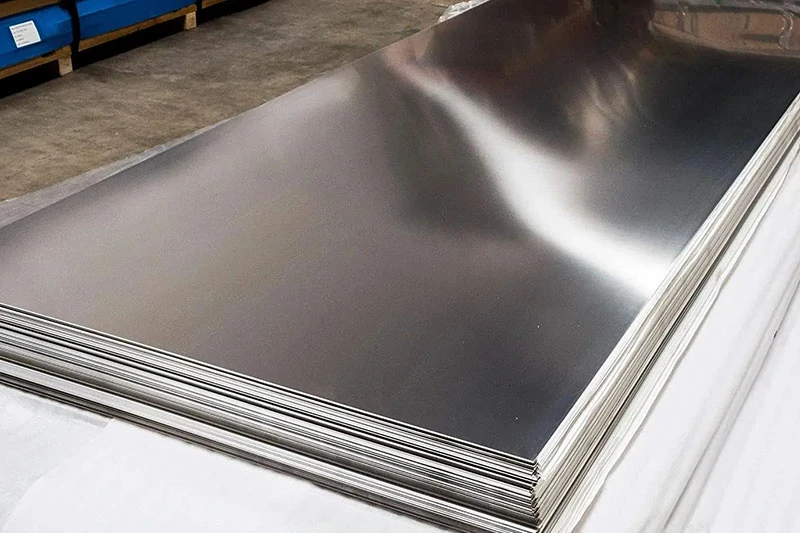

Ba – Excellent surface gloss, high reflectivity, like a mirror surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenching and tempering rolling.

No.3 — Good gloss, coarse grain surface.

Processing technology: polishing and tempering rolling for 2D or 2B with 100~120 abrasive materials (JIS R6002).

No.4 — Good gloss, fine lines on the surface.

Processing process: polishing and tempering rolling for 2D or 2B with 150~180 abrasive materials (JIS R6002).

HL — Silver grey with hair streaks.

Processing technology: 2D products or 2B products with appropriate granularity of abrasive materials for polishing the surface is a continuous abrasive grain.

MIRRO — Specular.

Processing technology: 2D products or 2B products with appropriate granularity of the grinding material grinding and polishing to the mirror effect.

Price List

| Stainless Steel 304L Plate Price List | 304L Plate FOB Per Unit (USD) | |||||||

| 304L stainless steel Plate | $1200.00-$1800.00 | |||||||

| 304L mirror stainless steel Plate | $1500.00-$2000.00 | |||||||

| Stainless Steel Plate 304L | $1200.00-$1800.00 | |||||||

| Standard size 4×8 metal sus 304L grade stainless steel checkered Plate prices | $1200.00-$1800.00 | |||||||