904L stainless steel, also known as Alloy 904L, is a high-alloy stainless steel that excels in corrosion resistance, especially in environments with strong acids, strong alkalis, and high chloride content. It demonstrates remarkable resistance to corrosive media such as sulfuric acid, hydrochloric acid, phosphoric acid, and nitric acid.

904L stainless steel finds applications in various industries, including chemical processing, marine engineering, oil and gas production, food processing, and medical equipment manufacturing. In chemical processing, it is used to fabricate reactors, storage tanks, pipelines, and valves due to its exceptional resistance to acids and alkalis. In marine engineering, its resistance to seawater corrosion makes it suitable for the construction of offshore platforms, oil drilling equipment, and seawater desalination facilities.

Equivalent Material

| Grade | Euronorm | China GB | Japanese JIS | |

| No. | ||||

| 904L | 1.4539 | 00Cr20Ni25Mo4.5Cu | SUS904L | |

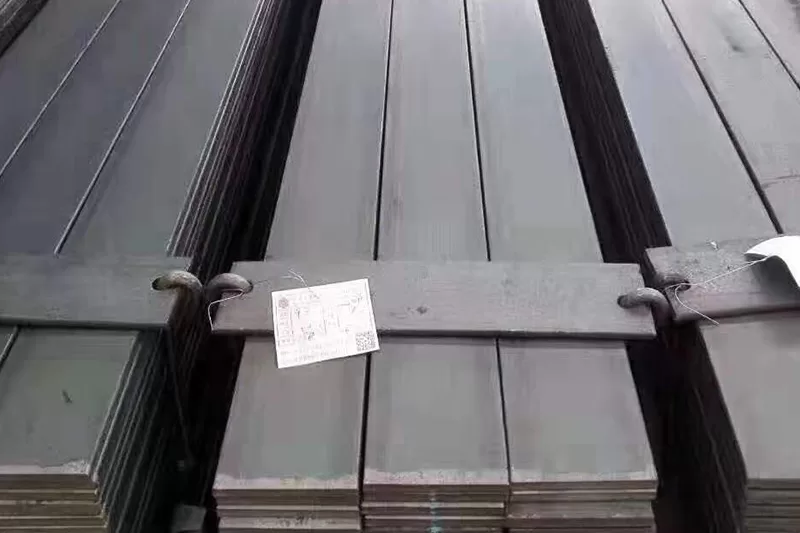

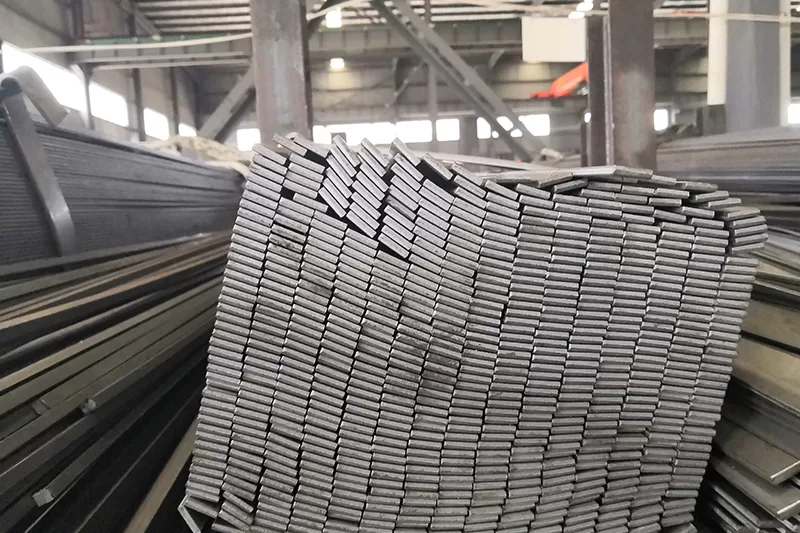

Standard Specification

| Thickness | 3mm-10mm | ||||||

| Width | 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, etc. | ||||||

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | ||||||

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc | ||||||

| Finish | Hot rolled flat steel(HR), Cold rolled flat steel(CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) | ||||||

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

||||||

Composition Content

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | |

| 904L | Min. Max. |

≤0.03 | ≤2.00 | ≤1.00 | ≤0.035 | ≤0.03 | 18.0-20.0 | 3.0-4.0 | 23.0-25.0 | 4.0-5.0 |

Alloy and state :926,

Tensile strength (Rm N/mm2):490

Yield strength (RP0.2N/mm2):216,

Elongation A5% :35.

Density: 8.24 g/cm3

Characteristic machining technology

1D — The surface has discontinuous granular shape, also known as fog surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2D – A slightly silvery white colour.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2B — Silver white with better gloss and flatness than a 2D surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + quenching and tempering rolling.

Ba – Excellent surface gloss, high reflectivity, like a mirror surface.

Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenching and tempering rolling.

No.3 — Good gloss, coarse grain surface.

Processing technology: polishing and tempering rolling for 2D or 2B with 100~120 abrasive materials (JIS R6002).

No.4 — Good gloss, fine lines on the surface.

Processing process: polishing and tempering rolling for 2D or 2B with 150~180 abrasive materials (JIS R6002).

HL — Silver grey with hair streaks.

Processing technology: 2D products or 2B products with appropriate granularity of abrasive materials for polishing the surface is a continuous abrasive grain.

MIRRO — Specular.

Processing technology: 2D products or 2B products with appropriate granularity of the grinding material grinding and polishing to the mirror effect.

Price List

| Stainless Steel 904L flat steel Price List | 904L flat steel FOB Per Unit (USD) | |||||||

| 904L stainless steel flat steel | $3800.00-$6500.00 | |||||||

| 904L mirror stainless steel flat steel | $4000.00-$7800.00 | |||||||

| Stainless Steel flat steel 904L | $3800.00-$6500.00 | |||||||

| 5mm thick stainless steel flat steel | $3800.00-$6500.00 | |||||||